Propeller shaft earthing systems

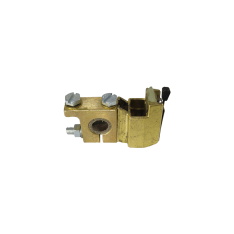

Monitoring brush for Propeller Shart Earthing System.

It is absolutely necessary to electrically ground the ship's propeller shaft to the hull. Because a rotating propeller generates a voltage potential difference between the shaft and the hull, which in time will case damage to the propeller and the bearings.

This voltage potential difference is generated because of the lubricating oil films in bearings and non-metallic materials resulting in electrical isolation of the shaft. The heavy electrical current flowing through the bearings and gearbox to the hull will be minimized by our earthing system, in order to prevent corrosion and damage.

The system is optimized by using silver graphite brushes with high silver composition and double brush holders for optimal contact an lowest resistance.

For more information about the installation of the Propeller Shaft Earting System download the user manual with instructions and technical drawings.

Request a quotation today or leave your details to receive more information from one of our experts.

Not exactly what you’re looking for? We offer standard products, but can also help you with a tailor-made or fully customized solution. Please contact us for advice or budgetary pricing.

Talk to an expertNeed something else?