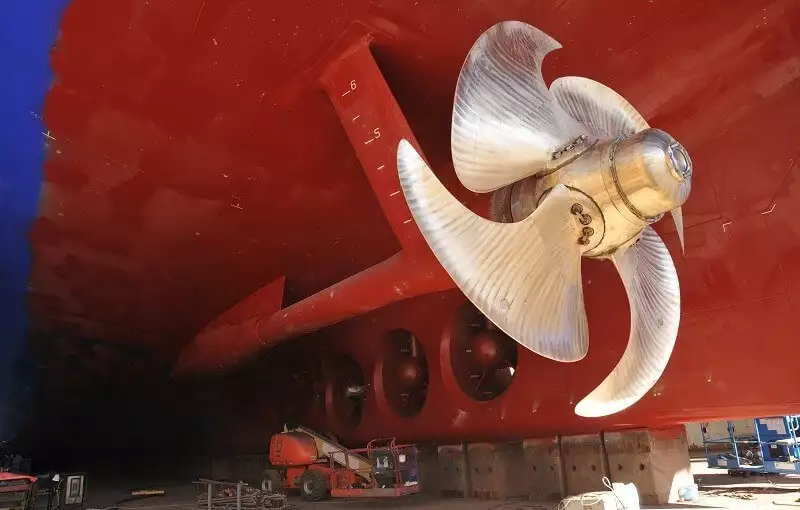

Propeller shaft earthing systems

8047A-8047M Propeller Shaft Earthing and Monitoring System

- Complete system

- Propeller shaft earthing set

- Cabin monitoring system included

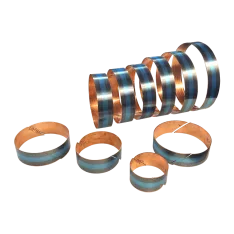

SE2100045-1 Silver/Copper Strip for Slipring

- Copper slipring with solid silver inlay

- Shaft diameters Ø100 - Ø1400 mm

8047A Propeller Shaft Earthing Set

- Complete monitoring set

- Indispensable for seagoing ships

- Directs electrical current that flows through the propeller shaft to the hull of the ship

8047M Potential Monitoring Set

- Optimal functionality

- Including brushholder

- Analog mV-meter

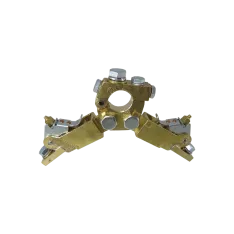

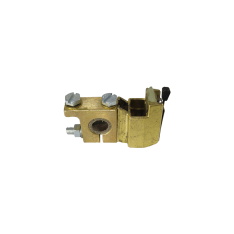

SE2100045-2 Earthing Brushholder

- Brushholder is part of Propeller Shaft Earthing System

- Double balancing

- Pressure setting

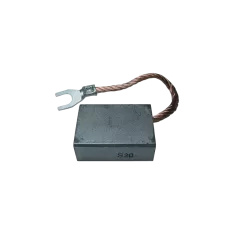

SE2400081 Earthing brush

- Brushes for propeller shaft system - 80% silver and 20% graphite.

- Must be mounted on a Ø12mm rod

SE2200014 Monitoring Brushholder

- Proven and optimized system

- Must be mounted on a Ø12mm rod

- Fixed spring that provides the right amount of pressure

SE2400082 Monitoring Brush

- Monitoring brush

- Silver/graphite brush (80%Ag)

- Dimensions: 20 x 10 x 32 mm.

Essential for sea-going vessels

To effectively channel the electrical current flowing through the propeller shaft into the ship's hull, a reliable grounding system with minimal electrical resistance is essential. At the heart of the Althen PSE System lies a copper slipring featuring a solid silver inlay, complemented by two stainless steel clamping bands equipped with dedicated connectors. To ensure seamless electrical continuity, the slipring is equipped with two silver/graphite brushes (comprising 80% silver), housed in a brush holder. This holder is then securely connected to the ship's hull via an earthing cable. This meticulously engineered setup not only optimizes electrical flow but also contributes to reducing the overall cost of ownership.

- Long service life of the system due to the high silver content in the brushes

- Single or double brush holders possible

- Low ohmic resistance due to wide slip ring in combination with the two almost pure silver brushes

- For variable shaft diameters Ø100 - Ø1400 mmSpecial monitoring set (also available as a complete solution )

Additional monitoring kit in the engine room

In tandem with the PSE system, an optional monitoring kit can be installed within the engine room to monitor the potential difference between the propeller shaft and the hull. This monitoring system includes an additional brush holder fitted with a single brush that interfaces with the slipring's silver track. Insulated from the hull, this brush holder is connected to an analog mV-meter, providing real-time feedback on the proper functioning of the PSE system. What's advantageous about this monitoring setup is its self-sufficiency, operating independently of external power sources. The analog mV-meter featured in the monitoring unit has a detection range spanning from 0 to 500mV.

mV-meter and converter for security

A properly functioning shaft earthing set should yield a reading below 50mV on the mV-meter. Any reading surpassing this threshold indicates a malfunction within the PSE system, possibly stemming from dirty or worn components, or incorrect installation. For added security, the monitoring kit can be augmented with a 4-20mA converter, introducing an additional alarm functionality. This feature can be invaluable, signaling to the bridge in the event of a potential difference exceeding safe parameters due to PSE system malfunction.

-

Exceptional electrical continuityOptimal electrical continuity, minimizing resistance and maximizing the efficiency of current flow.

-

Optional integrated monitoring solutionProactive oversight, alerting operators to any deviations from expected performance and facilitating timely maintenance interventions.

-

Cost-effective ownershipHelps mitigate the risk of costly downtime or repairs associated with electrical malfunctions.

Related projects

Would you like to get to know our products in practice?Related links

Safeguard the operation of your ship or vessel

Enhance maritime safety and ship performance with Althen Sensors & Controls' comprehensive range of Propeller Shaft Earthing System sets and individual parts. From copper sliprings to advanced monitoring solutions, our products are meticulously engineered for reliability and efficiency. Ensure seamless electrical continuity and mitigate risks with our trusted solution. Explore our products now and safeguard your vessel's operation.

How can we help you with your application?

We offer propeller shaft earthing systems but can also help you with further measurement solutions for the maritime industry.